The fluid polishing machine relies on the high-speed flow of liquid and the abrasive particles it carries to clean the surface of the workpiece, and then achieve the purpose of polishing. The commonly used methods for abrasive flow manufacturers include abrasive jet machining, liquid jet machining, fluid dynamic grinding, etc. Hydraulic grinding is driven by hydraulic pressure, allowing the liquid medium carrying abrasive particles to flow back and forth on the surface of the workpiece at high speed. The medium is mainly made of special composite polymer materials, which have good flowability under low pressure and are mixed with abrasives. Abrasives can be made from silicon carbide powder.

Six types of magnetic grinding and polishing: Magnetic grinding and polishing use magnetic abrasives to form an abrasive brush under the action of a magnetic field to grind workpieces. The abrasive flow manufacturer's method has high processing efficiency, good quality, easy control of processing conditions, and good working conditions. Using suitable grinding agents, the surface roughness can reach Ra0.1 μ M. The polishing mentioned in plastic mold processing is very different from the external polishing required by other professions. Strictly speaking, the polishing of the mold should be referred to as mirror finish. It not only has high requirements for polishing itself, but also has high standards for surface flatness, smoothness, and a few degrees of accuracy. External polishing usually only requires a shiny appearance.

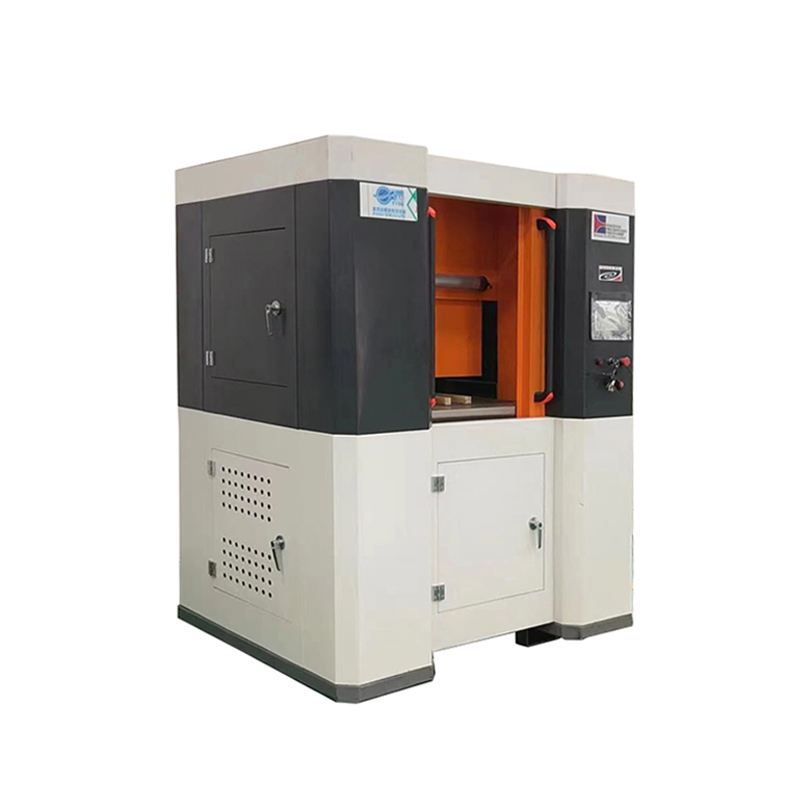

Fluid polishing equipment

Which parts can be polished through abrasive flow polishing process?

The abrasive flow polishing process of abrasive flow manufacturers is an environmentally friendly, efficient and automated surface treatment skill that has been widely used in the final stage of workpiece processing and surface treatment. Of course, the abrasive flow polishing process also has its advantages. Next, our abrasive flow manufacturer will introduce the applicable fields of this process:

1. Inner hole, cross hole; 2. Micropores; 3. Impeller blades; 4. Gear; 5. Irregular shapes and irregular parts; 6. Surface and sphere. 7. 3D printed parts.

The seven most common types of abrasive flow polishing processes from the above abrasive flow manufacturers. Of course, this does not mean that abrasive flow can only achieve these things. In fact, this process has a wide range of applications.